Introduction

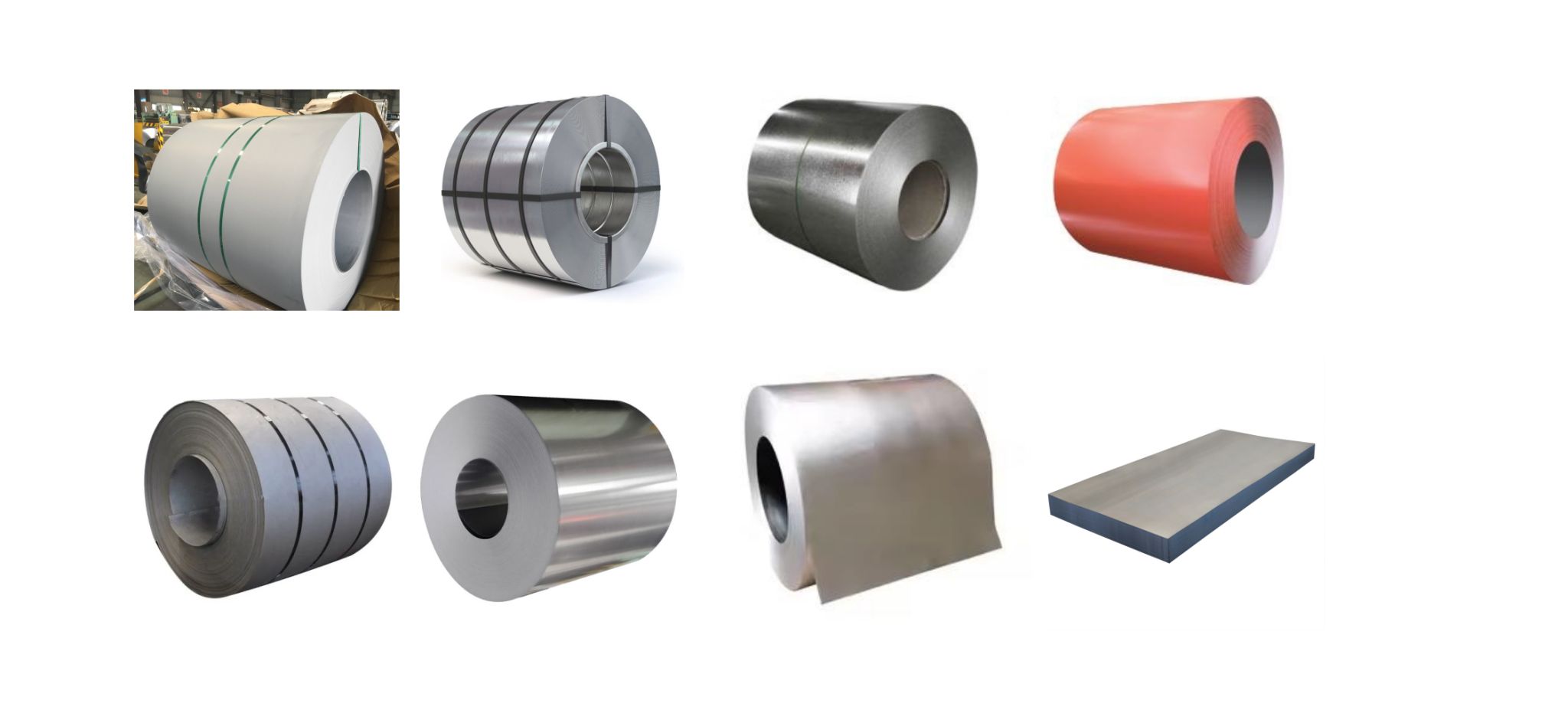

Mono colored steel is a premium construction material produced through a specialized color coating process. The standout features of mono colored steel include high durability, excellent corrosion resistance, and aesthetic appeal. This type of steel has become a top choice for many modern construction projects due to its superior advantages.

The Production Process

The production process of mono colored steel includes the following main steps:

- Raw Material Preparation: Steel raw materials are meticulously selected to ensure the highest quality.

- Surface Cleaning: Before color coating, the steel must be thoroughly cleaned to remove impurities, dirt, and grease. This step often involves sandblasting or chemical cleaning.

- Color Coating: The steel is color-coated using dipping in a color coating solution. This process ensures that the color layer adheres firmly to the steel surface, creating a robust protective layer.

- Drying and Heat Treatment: After color coating, the steel is dried and heat-treated to fix the color layer, enhancing the material's durability and corrosion resistance.

- Quality Inspection: Finally, mono colored steel undergoes rigorous quality inspection to ensure it meets technical and aesthetic standards before being shipped out.

Applications of Mono Colored Steel in Construction

Mono colored steel has numerous applications in the construction industry, including:

- Structural Construction: Mono colored steel is widely used in structural projects such as building frames, bridges, and other load-bearing structures. Its high durability and corrosion resistance help extend the lifespan of these constructions.

- Roofing and Cladding: It is an ideal material for roofing and cladding due to its aesthetic appeal and weather resistance. The diverse color options of mono colored steel also help create visually striking and unique buildings.

- Interior and Exterior Decoration: With its sleek appearance and various color choices, mono colored steel is often used in interior and exterior decoration, from doors and windows to smaller decorative elements.

- Furniture Manufacturing: It is also applied in the manufacture of furniture such as tables, chairs, and cabinets due to its good load-bearing capacity and high aesthetic value.

- Industrial Projects: In industrial projects, mono colored steel is used for making piping systems, storage tanks, and machinery equipment due to its excellent resistance to corrosion and chemicals.

The Strength of SYSTEEL VINA

SYSTEEL VINA stands out for its ability to provide high-quality coated steel products, serving both large projects and simple residential constructions. With its existing capabilities and reputation, SYSTEEL VINA hopes to be the best choice for our customers.

We continuously strive to research and develop new products while maintaining competitive pricing and professional, dedicated customer service. SYSTEEL VINA is committed to building a professional working environment based on aspiration, trust, creativity, teamwork, and continuous learning.

Related Posts:

SYSTEEL VINA: Your High-Quality Korean Pre-Painted Steel

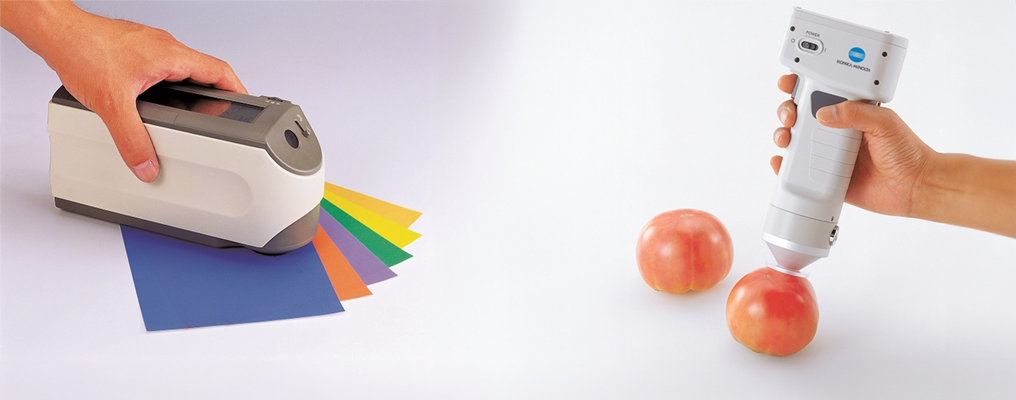

Distinguishing High-Quality Color Coated Steel: Tips from SYSTEEL VINA

Conclusion

Mono colored steel is an excellent solution for modern construction projects. With advanced production processes and extensive applications, mono colored steel not only enhances construction quality but also offers high aesthetic value. The use of mono colored steel in construction is a noteworthy trend contributing to the sustainable development of the construction industry.

548.jpg)