The manufacturing process of Vinyl Coated Line (VCL) involves an advanced technology system with stringent quality control to produce high-quality vinyl-coated metal products. Vinyl Coated Metal (VCM) from VCL exhibits corrosion resistance, durability, and aesthetic appeal, suitable for various industries such as household appliances and interior decoration. In this article, we delve into the detailed VCL production process and the diverse applications of VCM in modern life.

Vinyl Coated Line (VCL) Production Process:

Uncoiling:

The process begins with placing the steel coil onto the uncoiler machine, where the steel coil is unwound evenly and continuously. Technicians monitor and address issues like wrinkles, twists, or breaks to ensure the continuity and quality of the process.

Degreasing:

This step involves removing the protective oil layer and surface impurities from the steel substrate through degreasing solutions and water rinse systems. The clean surface is prepared for subsequent processing steps.

Pretreatment:

The pretreatment process removes the protective oil layer and creates a corrosion-resistant coating on the metal surface through pretreatment solutions containing chromate or phosphate. This process improves the adhesion of the steel substrate and the durability of the coating.

Coating:

High-quality primer paint is applied to the metal surface through precise and automated application processes. The paint layer is fully dried before proceeding to the next processing steps.

Base Oven:

The painted layer is air-dried to ensure complete drying without compromising the metal structure.

Lamination:

A PVC or PET laminate layer is applied to the pretreated and primed metal surface. Subsequently, the metal sheet is compressed and dried to ensure uniform lamination and complete drying.

Protection Film:

A protective film layer is applied to safeguard the final product from scratches and damage during further processing or transportation.

Rewinding or Cutting to Size:

The final product is rewound or cut into desired sizes before shipping and use.

The VCL production process delivers high-quality vinyl-coated metal products, meeting quality and technical standards, catering to various needs in modern life.

Strength of Vinyl Coated Metal (VCM):

High Aesthetic Appeal:

With a variety of designs, colors, and customizable options, VCM can be tailored to different customer requirements and replace various metal materials. Vinyl Coated Metal provides an attractive appearance suitable for diverse applications, whether for modern or classical aesthetics.

High Durability:

The protective film layer helps preserve the surface of the substrate, increasing the longevity of the finished product. This protective layer shields the metal from corrosion, scratches, and other forms of wear and tear, ensuring visual appeal over an extended period.

Processability:

Vinyl Coated Metal from Lienchy can easily undergo various manufacturing processes such as marking, bending, punching, and more. Its ability to maintain integrity in these processes prevents peeling or warping, making it versatile for different processing requirements.

Chemical Resistance:

This material can resist acids, alkalis, and other chemicals, making it suitable for environments exposed to these substances. This resistance ensures the material retains its integrity and structure even in harsh chemical environments.

Non-Toxic and Mold-Resistant:

Vinyl Coated Metal complies with RoHS standards, ensuring it does not contain harmful substances. Additionally, its mold-resistant properties make it ideal for applications in high humidity and wet environments, such as kitchens or bathrooms, without compromising safety or hygiene standards.

Applications of VCM in Modern Life:

Entrances:

Vinyl Coated Metal (VCM) is an ideal material for making entrances in buildings, apartments, and commercial establishments. The combination of high aesthetics and durability creates beautiful and sturdy entrances. With corrosion-resistant vinyl coating, VCM protects doors from weather and environmental impacts, ensuring long-lasting durability and keeping doors fresh throughout their use.

Elevators:

In elevator systems, Vinyl Coated Metal (VCM) is not only a strong material but also a part of modern interior design. With corrosion resistance and high durability, VCM is used to make walls and surfaces in elevator cabins, creating luxurious spaces and protecting elevators from surrounding environments.

Interior Design:

Vinyl Coated Metal (VCM) is an ideal choice for interior design due to its perfect combination of aesthetics and durability. From wall panels to interior details like cabinets, desks, and chairs, VCM provides an attractive appearance and reliable durability. The corrosion-resistant surface of VCM helps protect interiors from scratches and daily wear and tear while creating aesthetic highlights in living spaces.

Maritime:

In the shipbuilding industry, Vinyl Coated Metal (VCM) is widely used as insulation and corrosion-resistant materials for various parts of ships. Its corrosion resistance and waterproof properties are essential factors in protecting and maintaining ships in harsh saltwater environments.

Washing Machines, Refrigerators:

Vinyl Coated Metal (VCM) is an ideal material for surface production in washing machines and refrigerators. With corrosion resistance and waterproof properties, VCM helps protect and enhance the aesthetics of these household appliances, ensuring longevity and long-term performance.

Electric Kettles, Rice Cookers:

In household appliances such as electric kettles and rice cookers, Vinyl Coated Metal (VCM) plays a crucial role in providing corrosion-resistant and heat-resistant surfaces. The combination of corrosion resistance and heat resistance ensures these appliances operate smoothly and reliably for extended periods.

In summary, Vinyl Coated Metal has a wide range of applications from interior design to industrial use, from household products to transportation industries, thanks to its aesthetic appeal, durability, and corrosion resistance.

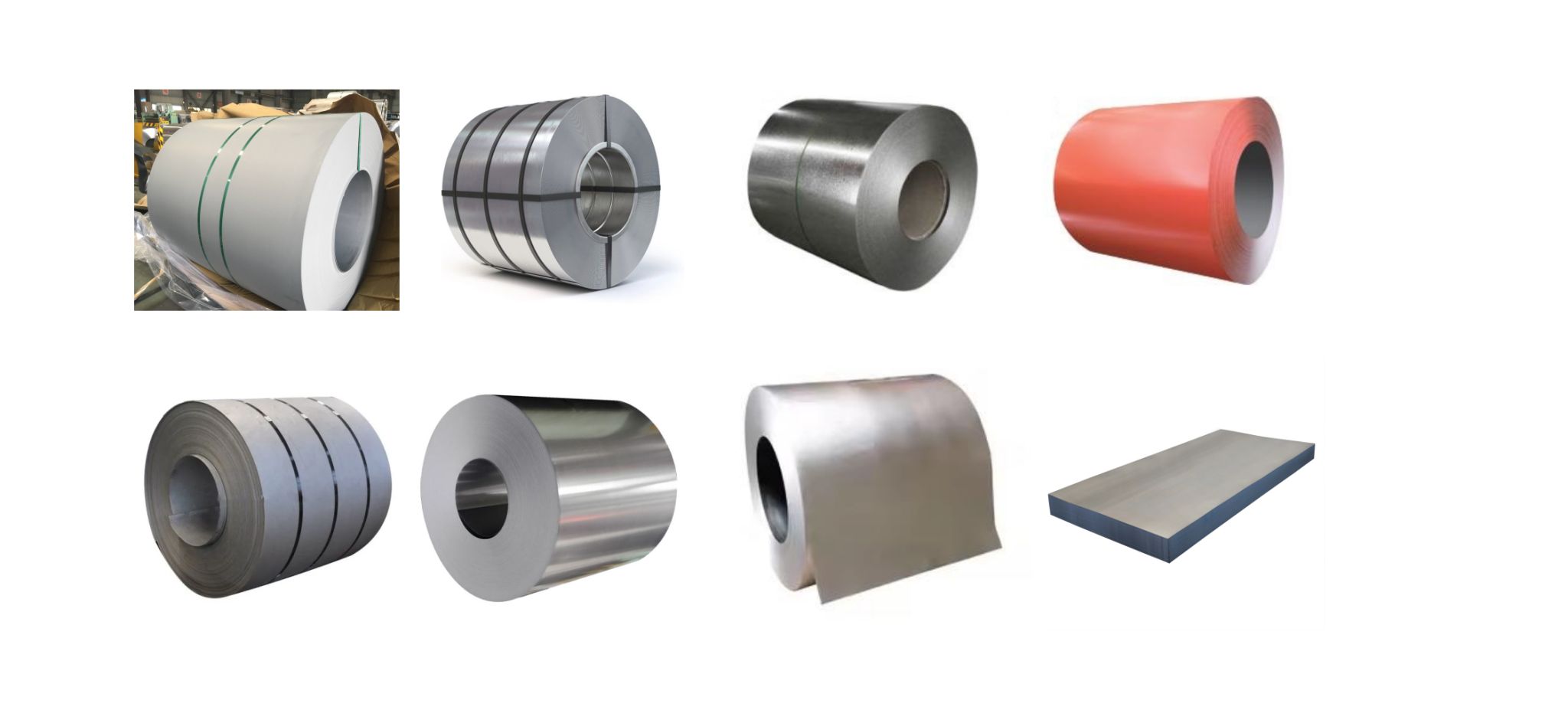

SY STEEL VINA's VCM Production Line:

SY STEEL VINA is proud to be a leading company in the field of laminate steel production in Southeast Asia, with an advanced VCM production line directly imported from South Korea. In particular, we focus on reducing production costs, thereby providing customers with high-quality VCM products, stable quality, and competitive prices. With the use of modern technology and strict quality management, we are committed to providing our customers with absolute satisfaction with products and services.

With over 30 years of experience in the colored steel manufacturing industry, SY STEEL is not only known as a reliable partner in South Korea and Vietnam but has also established a position in demanding markets such as Japan, the EU, and the United States. Additionally, our products are also popular in price-competitive markets such as India and Southeast Asia. This trust is built on providing high-quality products and the best warranty policies, thereby establishing long-term and sustainable partnerships with customers worldwide.

548.jpg)