Introduction to SYSTEEL VINA

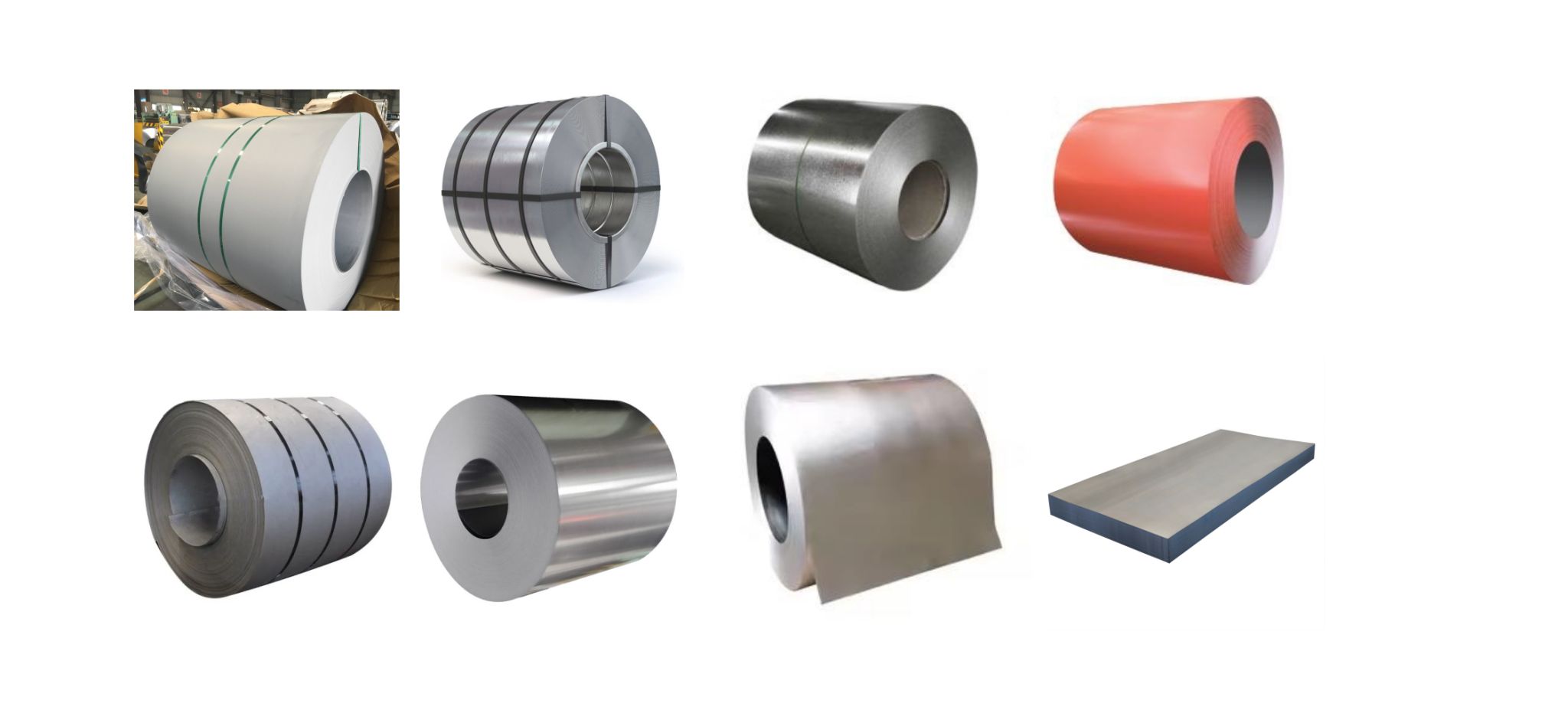

SYSTEEL VINA, a member of the Korean SY Group, specializes in the manufacture and distribution of high-grade pre-painted steel in Dong Nai, Southern Vietnam. With our modern factory and advanced technology, we provide high-quality pre-painted steel products to customers both domestically and internationally. Our products use a variety of base metals such as steel, aluminum, and stainless steel (SUS), combined with a wide range of colors and designs, to meet the most demanding customer requirements.

SYSTEEL VINA is proud to master three advanced manufacturing technologies: PCM (Pre-Coated Metal), VCM (Vinyl Coated Metal), and SSL (Shearing and Slitter Line) with a total capacity of over 190,000 tons per year. We are committed to producing top-quality products for the architecture and construction and home appliance industries, providing superior customer satisfaction.

SYSTEEL VINA's PCM Print Products

PCM (Pre-Coated Metal) is a pre-painted metal product with the following distinguishing features:

- Surface: Smooth and uniform due to the pre-coating before processing. This gives the product high durability and scratch resistance.

- Coating Thickness: Thicker coating than conventional painted products, increasing corrosion resistance and better protection against environmental factors.

- Colors: Diverse and can be designed according to customer requirements, ensuring flexibility in design and use.

- Applications: Used in the manufacture of refrigerators, washing machines, other household appliances, and in construction projects that require high aesthetics.

SYSTEEL VINA's VCM Products

VCM (Vinyl Coated Metal) is a vinyl-coated metal product with the following distinguishing features:

- Surface: Glossy and vibrant colors thanks to the vinyl coating. This surface not only provides high aesthetics but also has effective water and scratch resistance.

- Coating Thickness: Thicker vinyl coating than conventional metal products, enhancing resistance to chemical and mechanical impacts.

- Colors and Patterns: Can be printed with custom patterns and colors, providing customers with a wide range of choices for decoration and design.

- Applications: Commonly used in the manufacture of refrigerators, electronic control panels, doors, and other interior decoration products.

How to Identify PCM and VCM Products

To clearly distinguish between PCM and VCM products, you can apply the following tips:

- Surface Check: PCM has a smooth and uniform surface, while VCM has a glossier and more vibrant surface.

- Thickness Test: Use coating thickness measuring tools to check. The coating of VCM will be thicker than PCM.

- Color and Pattern Observation: If the product has special patterns or colors, it may be VCM because VCM has the ability to print richer patterns and colors.

- Application Check: Products used in high-end appliances or projects that require high aesthetics are often PCM. While products that require high durability and corrosion resistance are often VCM.

Related Posts:

The Story of SYSTEEL VINA: A Journey of Growth and Market Leadership

SYSTEEL VINA: Leading in High-Quality Color-Coated Steel Production

Conclusion

Understanding the difference between PCM and VCM helps SYSTEEL VINA customers choose the product that best suits their needs. We are committed to providing high-quality products that ensure superior aesthetics and durability. If you need more information or advice, please do not hesitate to contact us.

548.jpg)