Highlights of the PCM and VCM Production Lines at SYSTEEL VINA

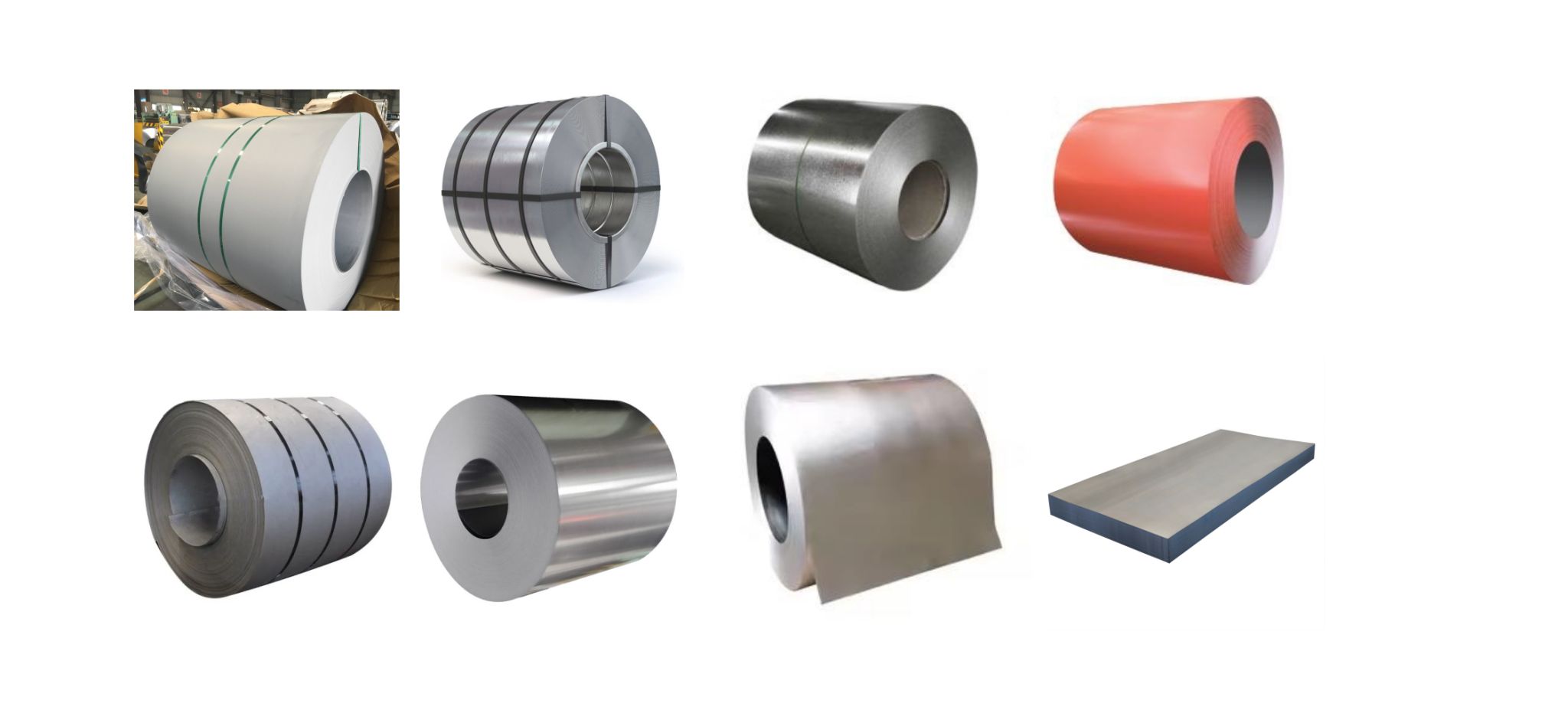

SYSTEEL VINA proudly leads the industry in the production of color-coated steel, delivering high-quality products with advanced manufacturing processes. Discover the strengths of our PCM and VCM production lines that help us create superior products to meet our customers' diverse needs.

PCM Color-Coated Steel Production Line

- Strict Process Control: Our PCM line includes steps from uncoiling, cleaning, surface treatment, primer coating, 3D pattern printing, top coating, embossing, to protective film application. Each step is rigorously quality-controlled to ensure perfect products following Korean technology and standards.

- Variety of Colors and Patterns: From solid colors, matte finishes to printed and embossed patterns, the PCM line offers numerous aesthetic options to meet all design and decoration requirements.

Vinyl Coated Line (VCM) Production

- Advanced Technology: The VCM line utilizes modern technology imported from Korea, encompassing processes from uncoiling, cleaning, surface treatment, applying PVC or PET laminate, to protective film application and recoiling.

- Durability and Aesthetics: VCM products boast corrosion resistance, durability, and high aesthetics, making them suitable for various applications from household appliances to interior decoration and transportation industries. SYSTEEL VINA's VCM line is the most advanced and unique technology in Southeast Asia.

Related Posts: SYSTEEL VINA - Leading Prepainted Steel Production Process

Vinyl Coated Line (VCL) Operation Process and Applications of Vinyl Coated Metal (VCM)

Outstanding Features of PCM and VCM Color-Coated Steel Products

- High Aesthetic Appeal: With a variety of colors and patterns, SYSTEEL VINA's color-coated steel products always meet strict design requirements.

- Exceptional Durability: Corrosion, scratch, and abrasion resistance help maintain the product's beauty over time.

- Flexible Processing: Easily undergoes processes like bending and punching without damaging the coating.

- Chemical Resistance: Resistant to acids, alkalis, and other chemicals, suitable for various environments.

- Non-toxic and Mold-resistant: Complies with RoHS standards, ensuring safety for users and being environmentally friendly.

Diverse Applications of VCM Products

- Doors, Elevators, Interior Design: Provides modern aesthetics and high durability for construction projects and interior design.

- Household Appliances: Suitable for surfaces of washing machines, refrigerators, kettles, and rice cookers, offering superior aesthetics and durability.

- Marine Vessels: Protects and insulates parts of ships in harsh saltwater environments.

Quality Commitment

SYSTEEL VINA is committed to providing customers with high-quality color-coated steel products that meet the most stringent market demands. With advanced production lines and a diverse product range, we strive to deliver absolute customer satisfaction.

Conclusion: Why Choose SYSTEEL VINA?

As a leader in the pre-painted steel manufacturing industry, SYSTEEL VINA not only provides superior quality products but also ensures customer satisfaction and trust. We use advanced technology and rigorous production processes to create pre-painted steel products with high aesthetics, superior durability, and diverse applications. SYSTEEL VINA is a reliable partner in the pre-painted steel industry in Vietnam and globally.

548.jpg)