SYSTEEL VINA proudly stands as a leader in the prepainted steel industry, delivering high-quality products through advanced production processes. This article details our production process, product range, and commitment to quality.

The PCM Prepainted Steel Production Process

Our PCM prepainted steel production process is conducted through numerous rigorous steps to ensure optimal quality:

- Uncoiling: Steel coils are unwound from large coils, preparing for subsequent processing.

- Entry Accumulator: Adjusts tension and provides initial shaping for the steel.

- Degrease: Cleans the steel with a degreasing solution to remove impurities.

- Hot Water Rising: Rinses the steel with hot water to remove residual cleaning solution.

- Pretreatment: Treats the steel surface with specialized chemicals to enhance paint adhesion.

- Primer Coater: Applies a primer layer to provide a foundation for the topcoat.

- Primer Oven: Dries the primer layer in a primer oven.

- Cooling: Cools the steel after drying.

- 3D Printing: Prints 3D patterns as required.

- Top Coater: Applies the topcoat with specified colors and patterns.

- Base Oven: Dries the topcoat in a base oven.

- Cooling: Cools the steel after drying the topcoat.

- Embossing: Embosses the steel to create special patterns.

- Tension Leveler: Adjusts tension and flattens the steel.

- Exit Accumulator: Final shaping and adjustment of the steel.

- Protective Film: Applies a protective film to the steel surface.

- Recoiling: Recoils the steel into large coils, preparing for transport.

Diverse Colors from the CCL Line

SYSTEEL VINA offers a wide range of colors and patterns from the CCL line, including:

- Mono Color: Solid colors.

- Matt Color: Matte finishes.

- Print Pattern: Printed patterns.

- Emboss - Leather Pattern: Embossed leather patterns.

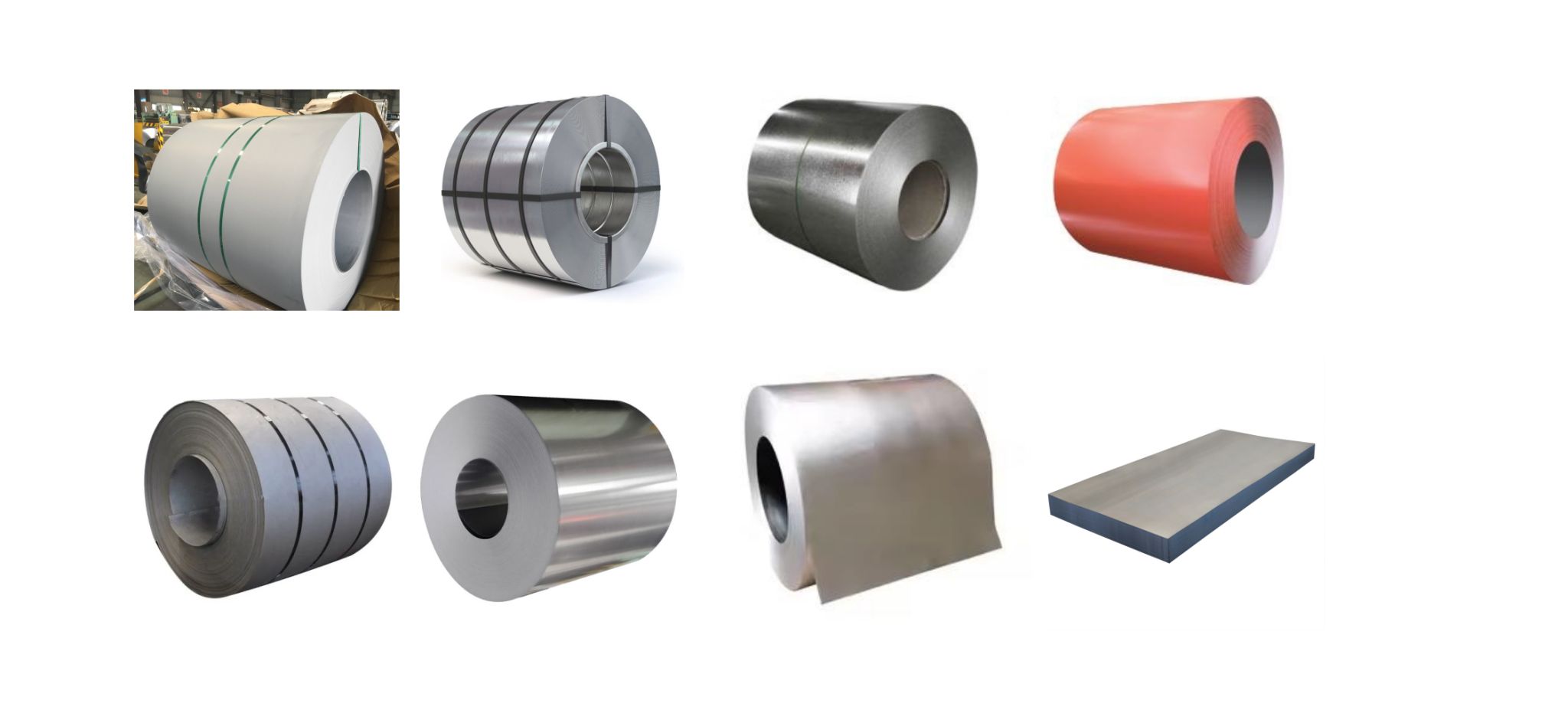

Highlighted Products of SYSTEEL VINA

SYSTEEL VINA produces a variety of prepainted steel products to meet all customer needs:

- RMP (Regular Modified Polyester): Medium performance, conventional coating.

- HDP (High Durability Polyester): Good performance, weather resistance, hydrolysis resistance, chemical resistance, and durability.

- SMP (Silicone Modified Polyester): Good performance, wear resistance, scratch resistance, and stamping processability.

- Matt: Attractive effect, good color retention.

- Print (RMP): Attractive pattern designs: shingles, hairline, wood, 3D, Corten, etc.

- PVDF (Poly Vinylidene Fluoride): Best performance in heat resistance, weather resistance, chemical resistance, and color retention.

- SY BIO (Ceramic-Metal): Antibacterial and antifungal, mainly used in operating rooms and clean rooms.

- SY Antistatic (HPP): Antistatic compound helps increase resistivity (10^6 to 10^8 Ω/cm^2), mainly used in high-tech works or places prone to fire and explosion.

- SY Cool Roofing (SQ-40CR): Reflects UV, excellent heat resistance, reduces interior temperature by 8-25%, lifespan of 40 years.

Related posts: Vinyl Coated Line (VCL) Operation Process and Applications of Vinyl Coated Metal (VCM)

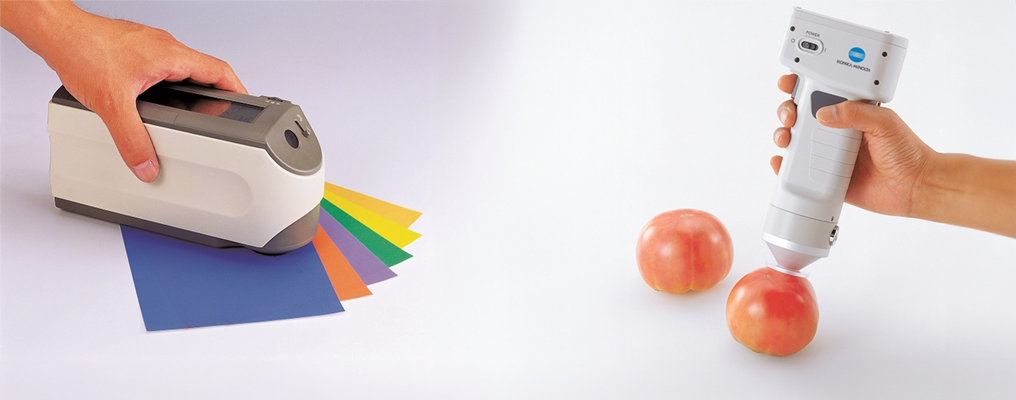

Distinguishing High-Quality Color Coated Steel: Tips from SYSTEEL VINA

Commitment to Quality SYSTEEL VINA

SYSTEEL VINA is committed to providing customers with high-quality prepainted steel products that meet the strictest market requirements. With our advanced production lines and diverse product range, we always strive to deliver absolute customer satisfaction.

548.jpg)